Licata Silicone render is a thin, ready-mixed top coat for external use that is highly breathable, with high water resistance, and excellent mechanical strength. Silicone Top Coat can be applied to Solid walls as well as Light weighed construction as long as the wall has been prepared by an appropriate base coat with a reinforcing mesh.

Pre-mixed, exceptionally breathable, hydrophobic and exhibits robust mechanical strength. Due to its high permeability, it is ideal for use as a decorative finish on those projects where water vapour is a potential issue. Flexible and durable it will protect your home or business for many years.

Silicone Top Coat Render range offers all the benefits listed below

![]() Silicone is self coloured

Silicone is self coloured

![]() Silicone is breathable

Silicone is breathable

![]() Silicone is easy to apply

Silicone is easy to apply

![]() Silicone looks great!

Silicone looks great!

![]() Ready to use

Ready to use

Description

Licata Silicone Render

Licata Silicone render thin coat is a ready mixed top coat for external use, highly breathable, high water resistance and excellent mechanical strength. Silicone render provides a high resistance to algae, fungi, mould and to atmospheric agents. The careful choice of acrylic binders and silicone, ensures good durability and a gloss finish with pearlescent effect to the water drops.

Licata Silicone Render is ideal as a decorative finish in all work requiring high permeability to water vapour. Our premium Silicone top coat formula provides flexibility and durability, ensuring your facade is protected for years to come.

Application

For application by hand, apply the product onto the substrate using a stainless steel trowel and mix it using the plastic trowel. Coating laying that is not applied in a single processing cycle, in an uneven or discontinuous manner could easily create chromatic alterations or “voids” in the coating pattern. The use of different types of trowels, or mixing with different circular trowel movements during application could compromise the homogeneity of the final appearance of the finish.

On internal substrates, a single coat of the product can be applied, whereas on external substrates, a double layer of render needs to be applied to ensure suitable thickness for protection against the weather. Make sure the temperature of the room and of the substrate during application falls between 5 °C & 30 °C.

Let’s take a minute to examine those benefits a little closer.

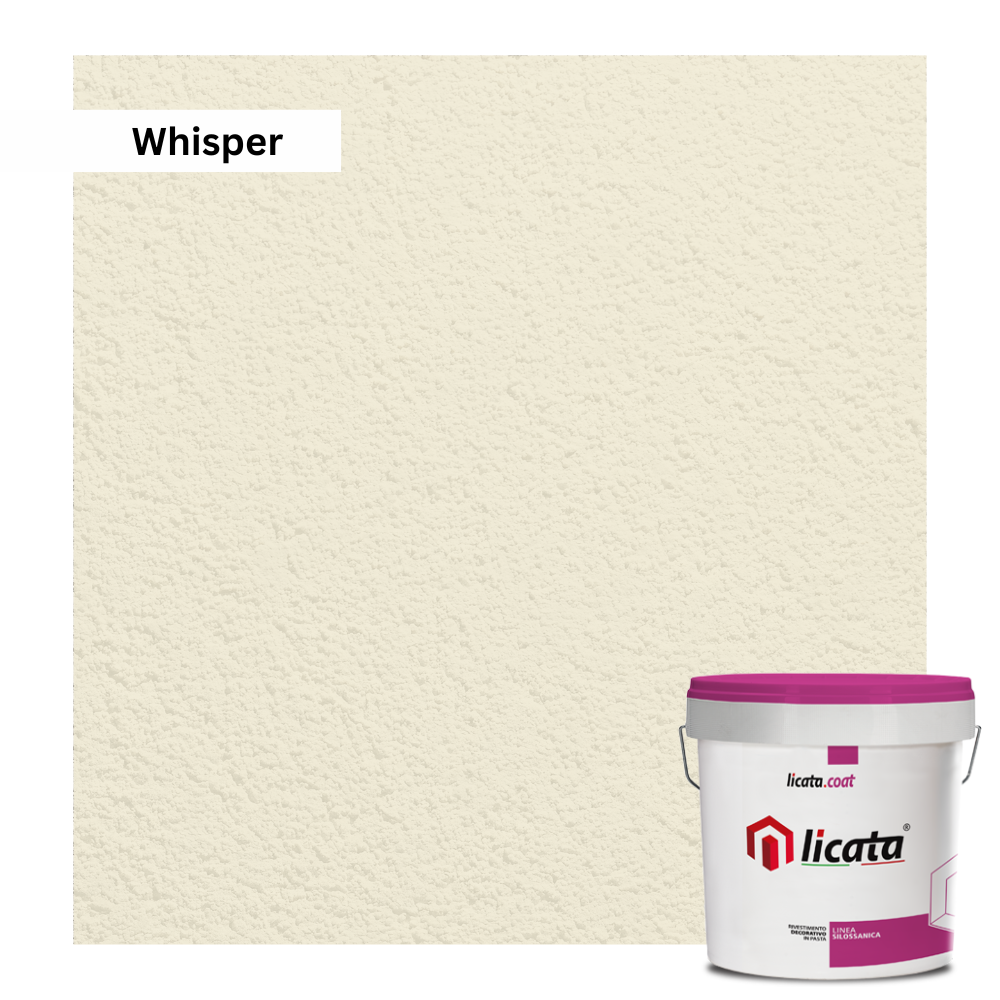

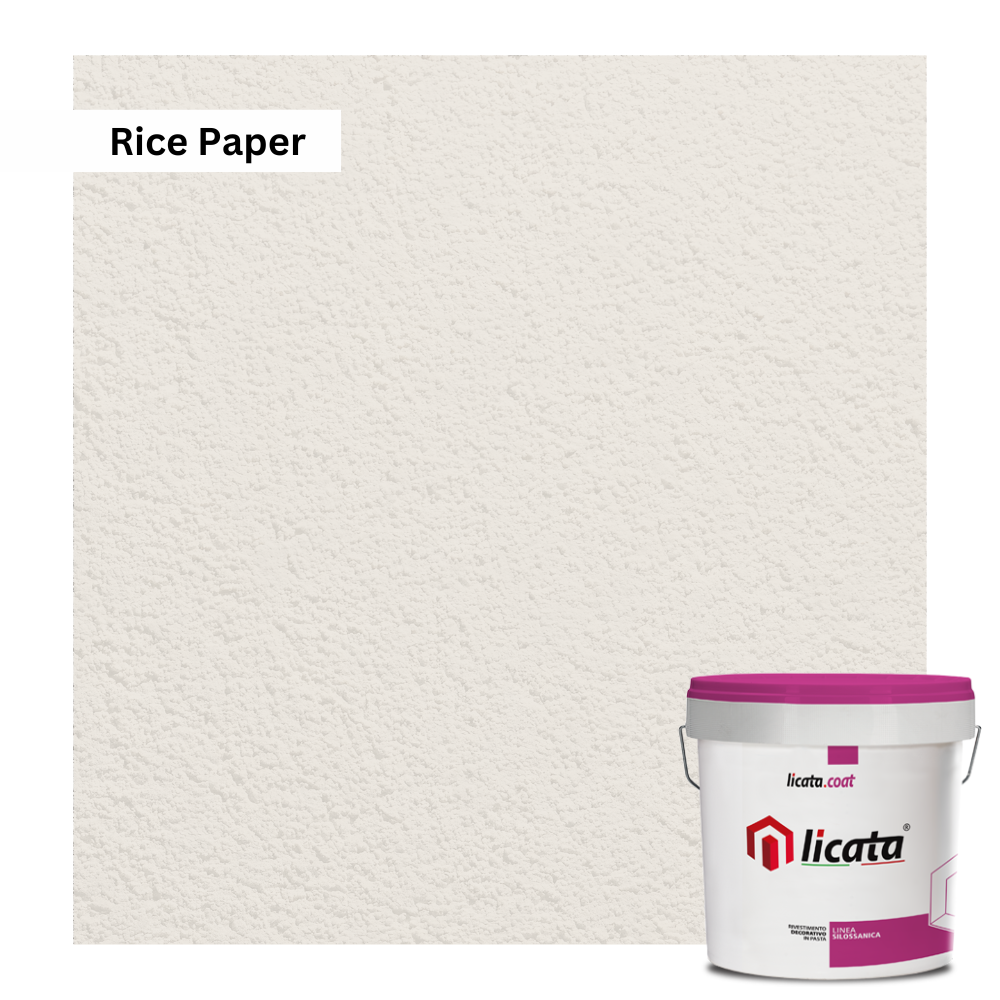

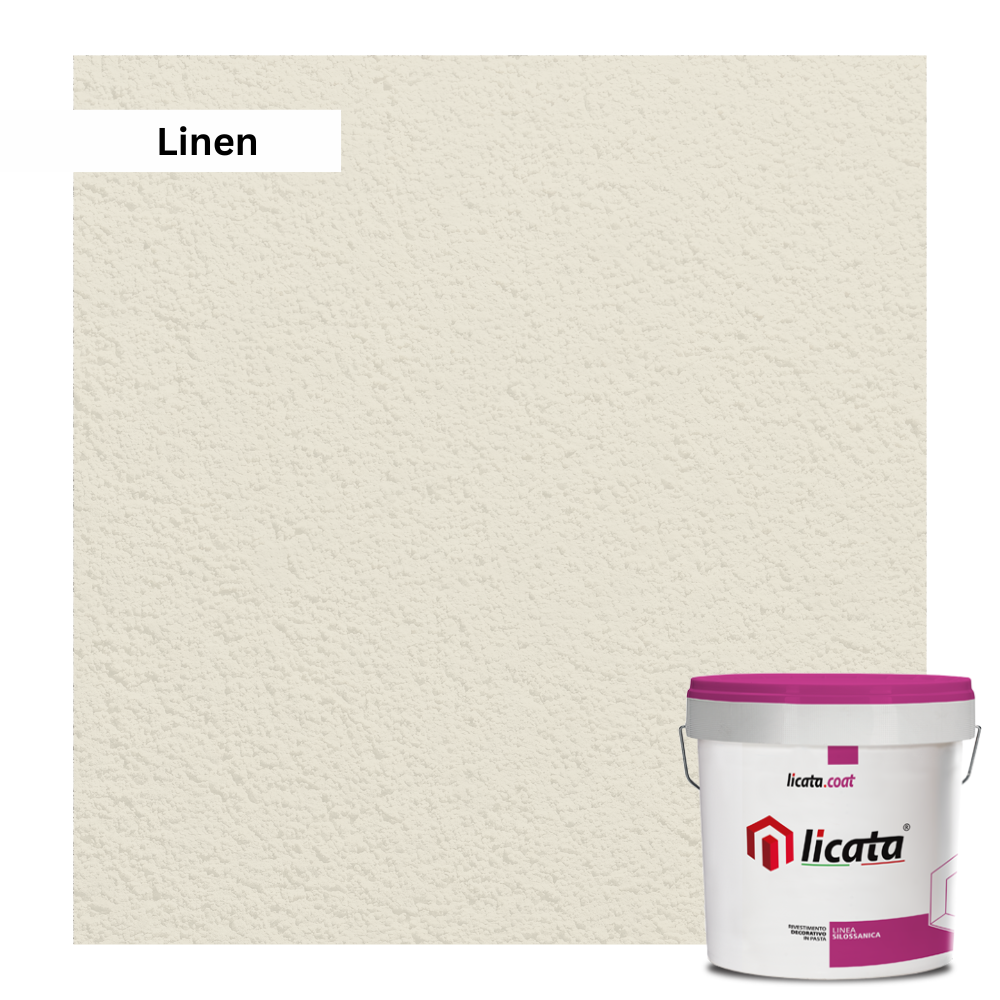

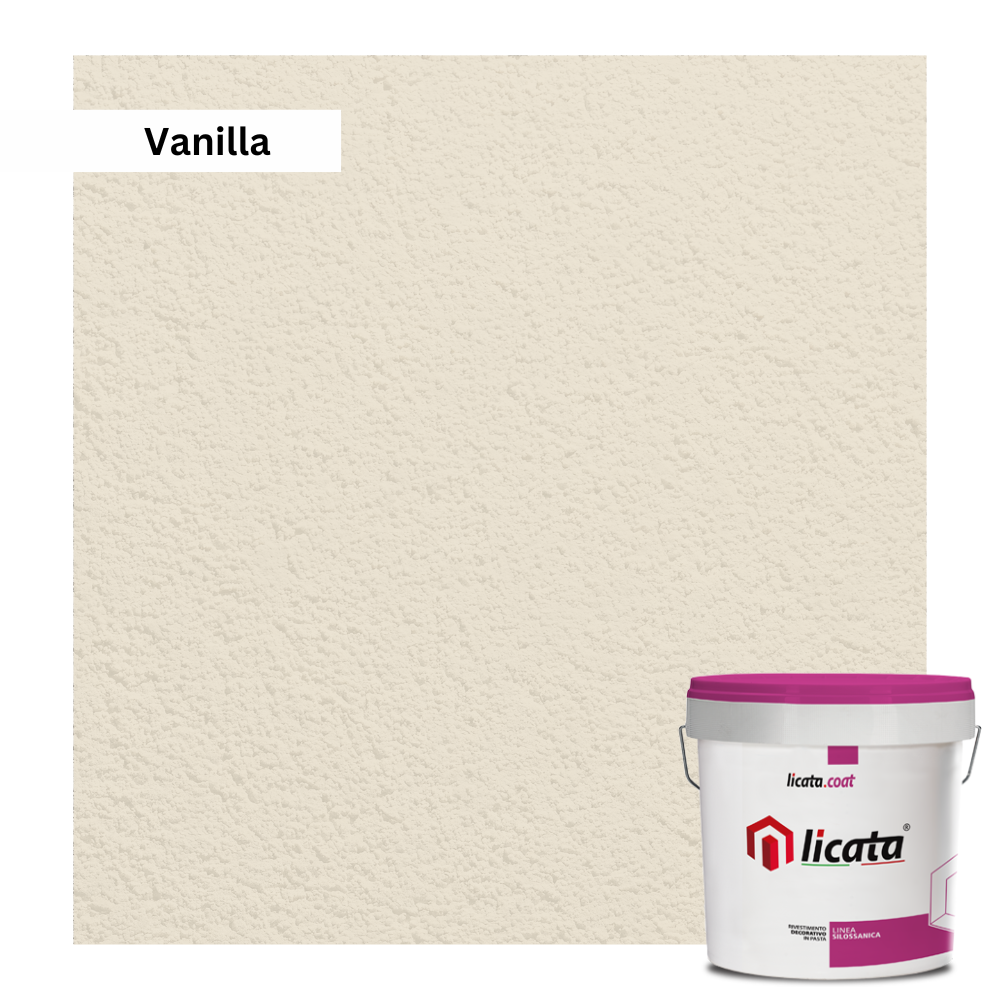

- Silicone is self-coloured – other types of external render need to be painted. That is not the case with a silicone topcoat render. Silicone renders are self-coloured. That is, the colour is added during the manufacturing process and permeates the silicone. There are a lot of advantages to this. First off you never have to paint the silicone (unless of course, you want to change colour at some future date). Second, because it’s not painted it won’t chip and flake. Third, scratches won’t show because the colour is the same all the way through. And finally, this type of topcoat render will last longer and cost less to maintain than a painted surface.

- Silicone render systems are breathable – if you render a wall with concrete or acrylic that wall becomes impermeable, which means any moisture that finds its way into the wall behind the concrete will be trapped there. Moisture trapped inside a wall can undermine the integrity of wooden joists as well as wiring and the external wall insulation. Not a pretty picture. Silicone is breathable, which means it allows moisture to pass through. If dampness is an issue where you live, a silicone render is likely the smartest choice.

- Silicone is easy to apply – other types of render typically call for more than one layer. After the material has been applied there is curing to take into consideration. And when the render has cured the material then needs to be painted. All of these steps add time and expense to the rendering process. With a silicone topcoat render there’s no curing and no painting to contend with. So while the silicone material itself is usually a bit more, the overall project can be less expensive because it can be done faster and it doesn’t require as many materials.

- A silicone render look great – silicone is considered the gold standard of render materials for all of the above reasons, and because a silicone render finish looks great. A silicone render will provide a smooth, appealing surface with a durable, uniform colour that is very hard to match using other materials like concrete and acrylic.

- Silicone topcoat renders are ready to use – with Licata silicone topcoat rendering there is no mixing or other preparation involved. They come ready to be applied. Compare that to a cement render which often entails a lengthy preparation process. With silicone, the only prep will be conducted on the surface itself.

- No painting required – because our silicone renders are through coloured the customer is free of the hassle and expense of painting it once it dries. This type of through coloured render will not chip and flake like externally applied paints will, nor will surface scrapes and dings be readily apparent.

- Outstanding aesthetic qualities – besides being breathable, through coloured, and easy to apply the silicone render has become popular in London because it looks great. The finished surface has an appealing uniform appearance, works well with a variety of architectural styles and the colour is bold without being ostentatious.

Silicone Render FAQs

What is a silicone render?

A silicone or “thin coat render” is just that; a thin outwardly facing render with a silicone base that is highly waterproof, flexible, durable, and cost-effective. The silicone render is through-coloured so there is no painting necessary and it is lightweight so it will not put undue stress on older walls.

Is the silicone render as good as it’s made out to be?

Absolutely. Besides all of the above attributes, the silicone render is also easy to apply, will not fade and is an ideal rendering solution for older homes or homes that are settling for one reason or another. As long as there is a robust base to apply it to the silicone render is an outstanding choice.

How long will a silicone render last?

Silicone is extremely weather-resistant, repels dirt, dust and other pollutants, is through-coloured so it won’t fade and will move if your house moves (within reason of course). For all of these reasons and more, you can expect up to 25 years from your silicone render.

Can you paint a silicone render?

You can if you wish, but why would you? This type of render material is through coloured so there is no need to paint and the surface appearance will not suffer (from a colour perspective) if it gets chipped or otherwise damaged.

Can I apply a silicone render over an existing render?

In most cases, yes, as long as the existing render is basically sound, free of cracks and the surface is free of dirt, grease, flaking paint or other types of contamination.

Is a silicone render waterproof?

Yes, a silicone render is waterproof. Its superb hydrophobic qualities are a huge selling point and one of the main reasons so many UK home and business owners opt for this type of render.

Will a silicone render crack?

Silicone is naturally resistant to cracking, but everything has its limits. While the type of subsidence experienced by many older homes should not be a problem, extreme cases of settling could possibly cause the rips in the surface. However, if the settling is that extreme it’s likely your house is unliveable.

FEATURES

| BBA & ETA Certified | Suitable for exterior application | ||

| Available in over 700 colours | Anti-mould and algae properties | ||

| Ready to use | Excellent workability | ||

| High water-resistance |

Additional Info

| Weight | 25 KG |

|---|---|

| Colours | 1/10 |

| Grain size |

|

| Consumption |

|