I’m Here To Assist You

Licata Building System needs your contact information to contact you about our products and services. Our specification manager will contact you shortly in regard to your enquiry.

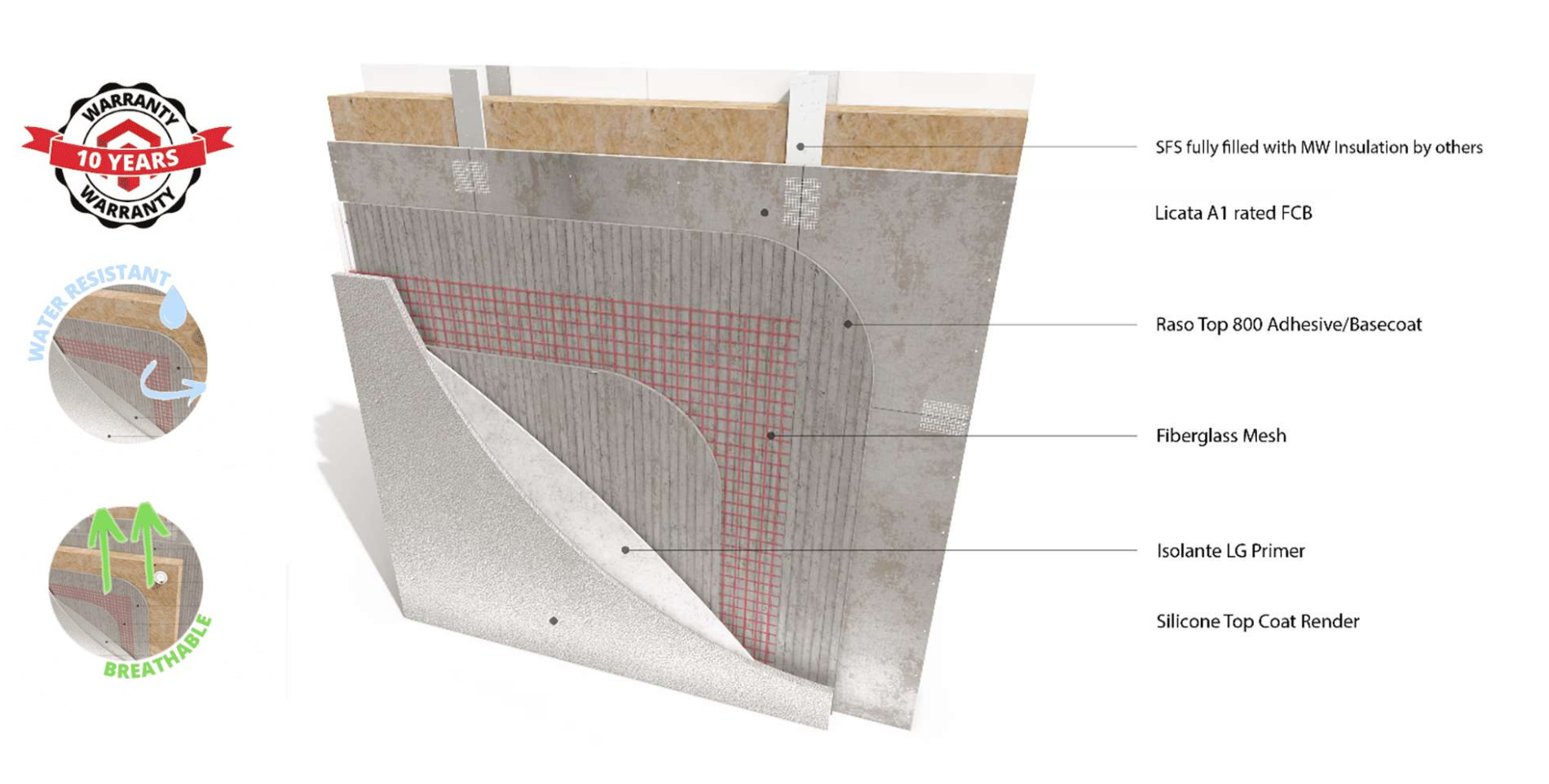

This render system offers a choice of products for the basecoat and decorative finish. Only one product from each section is required to complete the system. If clay brick slips are to be used as the decorative finish, an extra adhesive will be required (Super S1)

Cement board, or drywall as it is sometimes called, can be used as an exterior siding material for your house. It is also commonly used for interior walls. But what does it do? Cement board is a very durable material that has the ability to protect the inside of the wall from water damage and the outside from weathering. It does this by providing a barrier between the two parts of the wall. The cement board provides protection for any place where you might have plumbing or wiring, like in kitchens and bathrooms. It also has fire protection features and sound absorption features.

First and foremost, cement board is an excellent water-resistant material. It is resistant to the growth of mold and bacteria, which means that you won’t have to worry about any nasty smells or harmful substances being produced in your home. Cement board also has a long lifespan. It can last up to 50 years if it is used professionally. This means that it will not be necessary for you to replace it when the time comes. Another reason why cement board is so important is because it can be cut into different shapes and sizes. And because it is so easy to cut, you can use a variety of design techniques with it easily. It can also be installed quickly and efficiently, which means that you will save on both time and money when working with cement board for your project.

The most important advantage of using cement board is its affordability. Some may think that because it is not visually appealing, it would be expensive. However, this is not the case. It is a great alternative to more expensive materials such as bricks or tiles. In addition to being affordable, it also helps you make your project last longer and help you avoid wasting time and money. When using cement board, you will have a better chance at having a more durable project than if you used other materials (such as brick). Cement board can also help your project look better in the long run. It can help prevent water damage and make your construction project more resistant to mold growth.

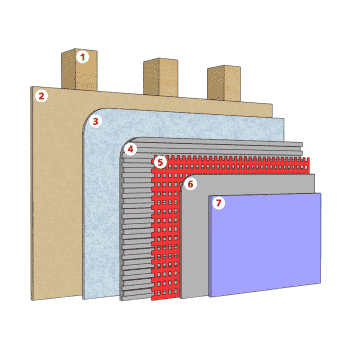

Panel substrate render boards offer a highly versatile solution for various building applications. These render carrier boards are compatible with thin coat render systems, making them suitable for a wide range of properties, from residential to commercial builds. With their advanced properties, they provide a strong and durable foundation for both internal and external applications.

This combination of features makes panel substrate render boards a reliable option for a wide variety of building projects.

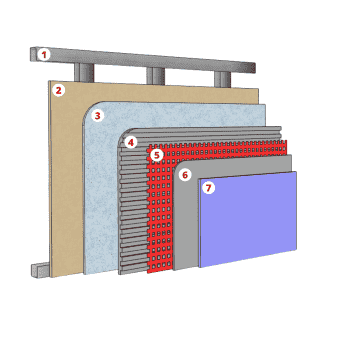

Thin coat render systems have become a popular choice in modern construction due to their efficiency and superior performance. These systems are especially effective when paired with render carrier boards, providing excellent results for external walls.

These features make thin coat render systems the perfect solution for both new builds and renovation projects, offering exceptional results in a fraction of the time.

The flexibility of render carrier boards allows them to be used across a variety of applications, making them an ideal substrate for both internal and external applications. Whether you’re working on a large-scale commercial building or a residential project, these boards provide a dimensionally stable and high-performance base.

Render carrier boards are often used in:

Their adaptability ensures they can be used across a variety of render systems, making them a highly practical option for many construction needs.

One of the major selling points of panel substrate render boards is their protective features. Designed to stand up to even the most extreme conditions, these boards help maintain the integrity of the building over time.

They are equipped with an alkali resistant mesh embedded within the system, which further improves the board’s overall strength and stability. This feature ensures that the render boards remain intact even when exposed to challenging weather conditions.

In addition to their impact resistance, these boards are also highly resistant to moisture, preventing issues like water damage, mould, and algae growth. This moisture resistance, paired with their fire resistance, makes them a top choice for high-performance building materials.

At Licata, we pride ourselves on delivering industry-leading solutions for all types of render systems. From panel substrate render boards to polymer modified render systems, our expertise ensures that your project benefits from the highest quality materials and professional support.

Whether you’re looking for advice on the best carrier board for your building or need guidance on implementing coat render systems, our team is here to help. With decades of experience, we ensure that your project is completed with precision and care.