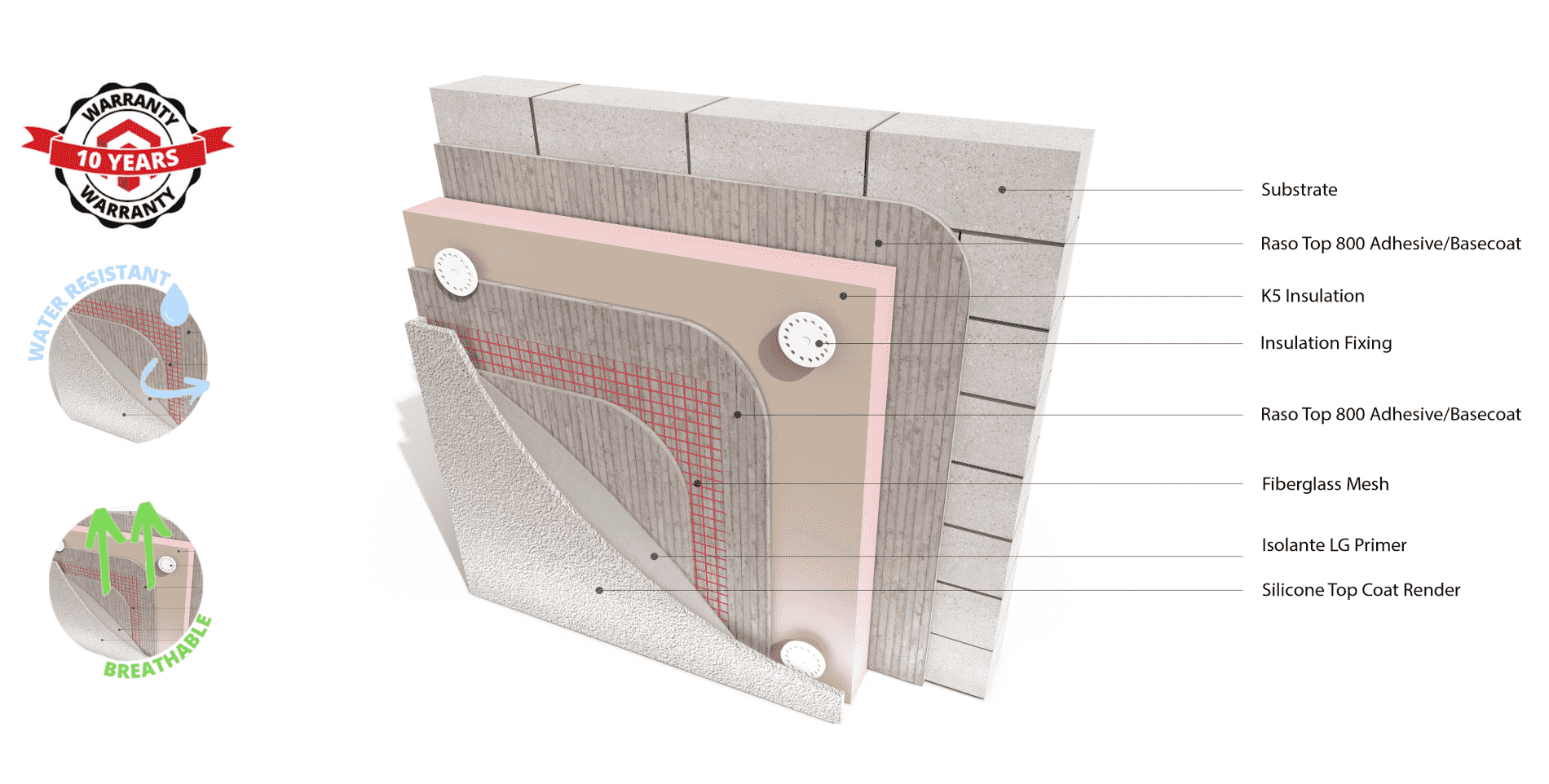

Enhancing Structural Durability with Fibreglass Mesh

Fibreglass mesh is a key component of our glass fibre mesh external wall insulation system, providing crucial wall reinforcement to prevent cracking. Embedded within the cement-based basecoat layer, it strengthens external walls, enabling them to withstand natural building movements. This reinforcement reduces the risk of structural damage, ensuring durability in both new builds and refurbishments.

The basecoat layer is applied slightly thicker in areas that need extra strength, working seamlessly with the fibreglass mesh to enhance the system’s integrity. Its alkali-resistant properties ensure long-lasting performance, even in challenging weather conditions. This reliable solution protects your external walls while maintaining structural integrity over time.

Key Installation Practices for Crack Prevention

Embedding fibreglass mesh into the basecoat adhesive is an essential step to prevent cracking in render systems. The mesh needs to be initially embedded into a wet cement-based basecoat layer, with vertical strips overlapped by at least 100mm for added reinforcement. This practice secures the glass fibre mesh external wall insulation system, ensuring it remains strong and flexible.

Once the first pass of the mesh is complete, a second layer of base coat render is applied to fully encapsulate it. This additional strengthening layer helps the system withstand impact and adjust to natural building movements. Proper installation ensures your insulated render system remains crack-free and highly durable.

Thermal and Fire Performance of Reinforced Systems

Our external wall insulation systems not only improve structural integrity but also enhance energy efficiency by reducing heat loss. By combining fibreglass mesh with expanded polystyrene or other insulation materials, these systems create a thermally efficient barrier. This helps homeowners save on energy costs while maintaining a comfortable interior environment.

Fibreglass mesh also plays a role in fire safety, particularly when paired with fire-resistant materials. It retains its structure under high temperatures, ensuring the external wall insulation system remains compliant with safety standards. This makes it a dependable choice for modern, energy-efficient buildings.

Flexibility and Strength in Dynamic Environments

Fibreglass mesh embedded in the basecoat layer adds both flexibility and strength to external wall insulation systems. This allows the system to adapt to natural building movements without cracking, maintaining its appearance and performance over time. Whether for new builds or refurbishments, this adaptability makes it a trusted solution.

With its age-resistant and impact-resistant properties, fibreglass mesh provides long-term reliability for insulated renders. From stress-prone areas to thin coat render systems, it ensures your external walls are protected, reinforced, and built to last.