Helping to Bring the Concrete Industry in Line with Sustainability Goals

Unknown to most people the global concrete industry is one of the largest contributors to climate change. It contributes a staggering 8% of all greenhouse gasses released into the atmosphere. That’s more than India and Japan combined. In fact, the only countries that release more CO2 into the air than the concrete industry does are the United States, and China.

How is that possible? It starts with the fact that one of the basic components of concrete, limestone – is fired in enormous kilns powered almost exclusively by fossil fuels. Then add in the fact that chemical reactions associated with the concrete manufacturing process produce even more CO2, and the bottom line is that producing 1 kg of concrete sends 1 kg of CO2 into the air. And since the world produces some 30 billion tonnes of concrete each year that means the industry also sends 30 billion tonnes of CO2 into the air each year.

This helps explain why there are several movements afoot that hope to rein in the concrete industry or, at the very least, make it more environmentally sustainable than it currently is.

Showing The Way

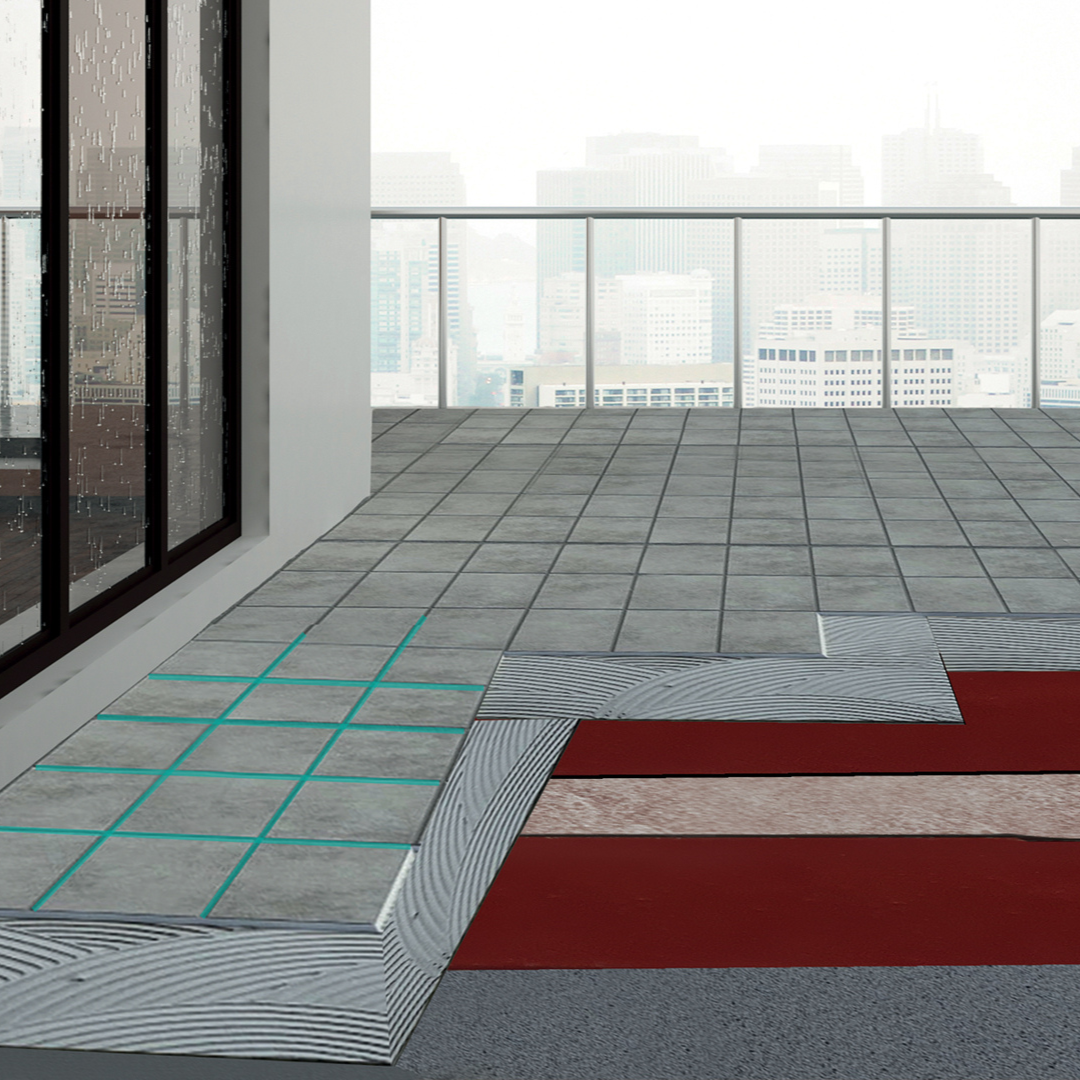

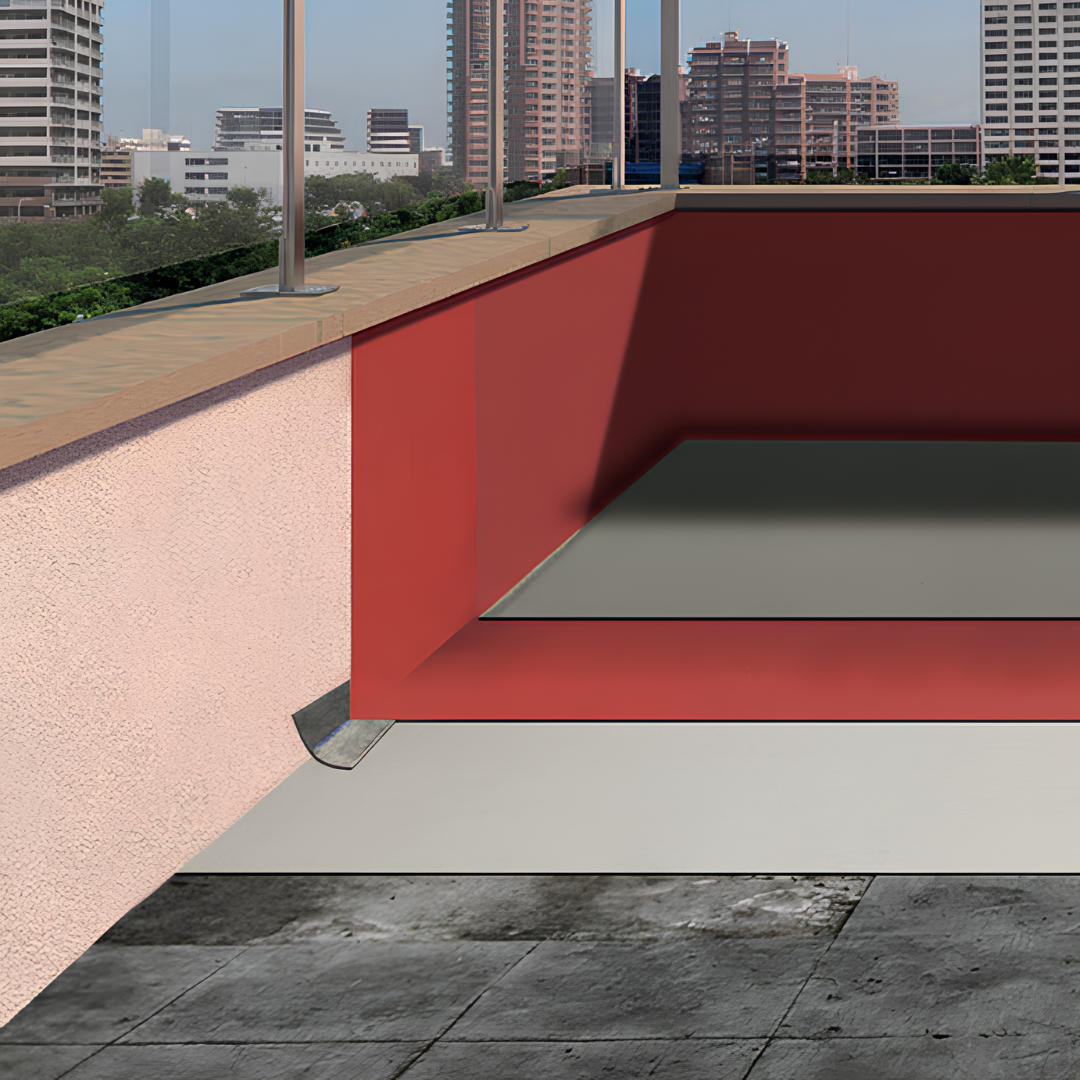

One of the ways to make the concrete industry more sustainable is to create products that help building owners, governments and others to get more life out of their existing concrete. Which is one of the reasons waterproofing systems from Licata are so important.

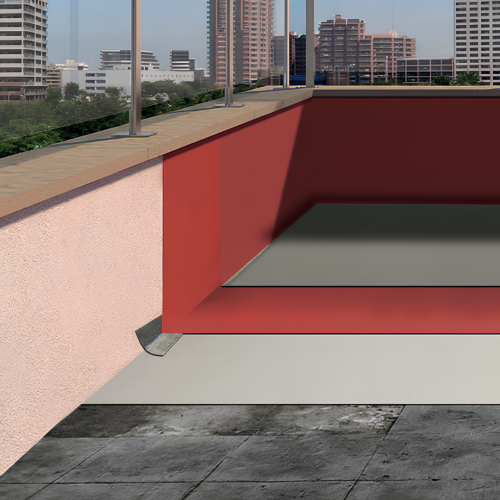

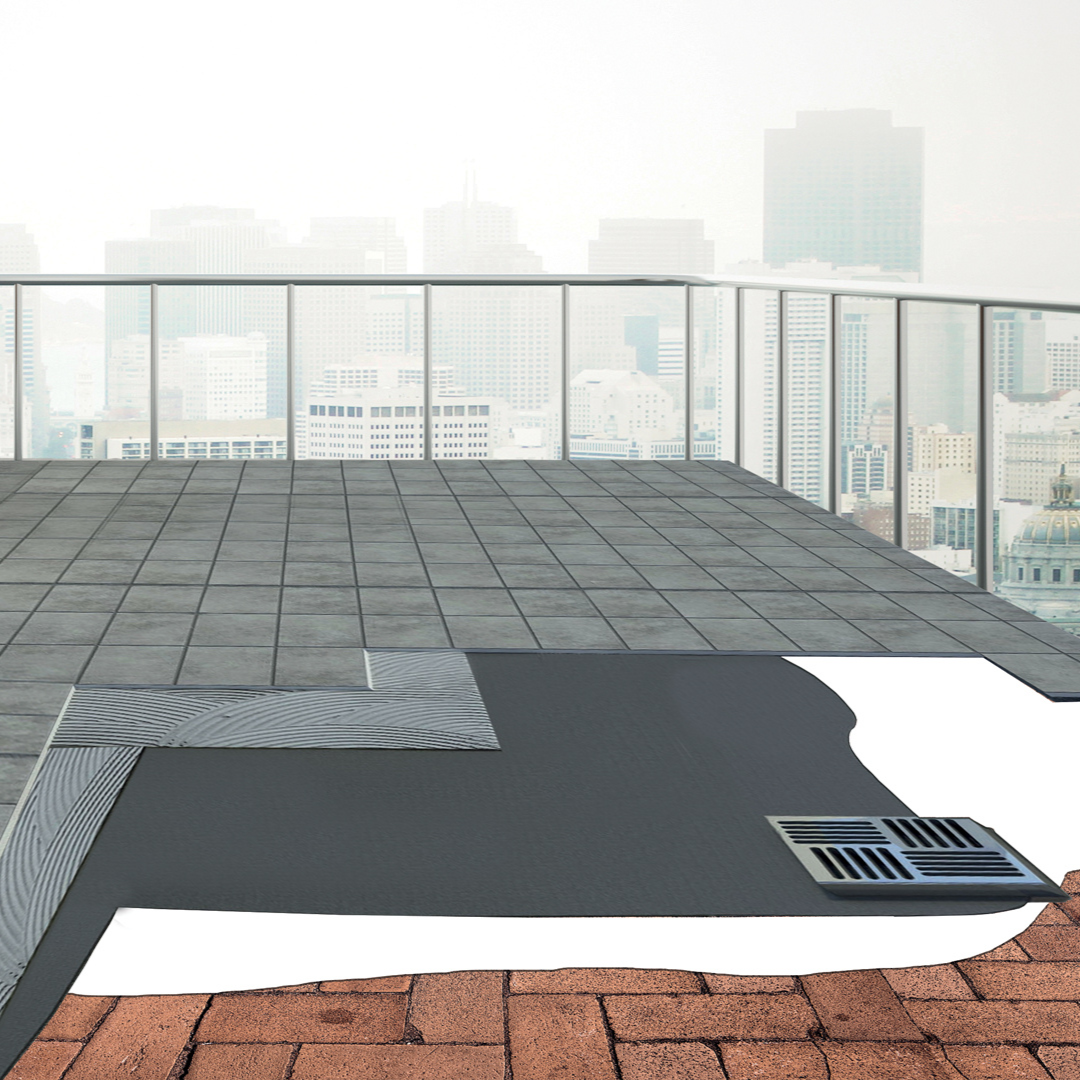

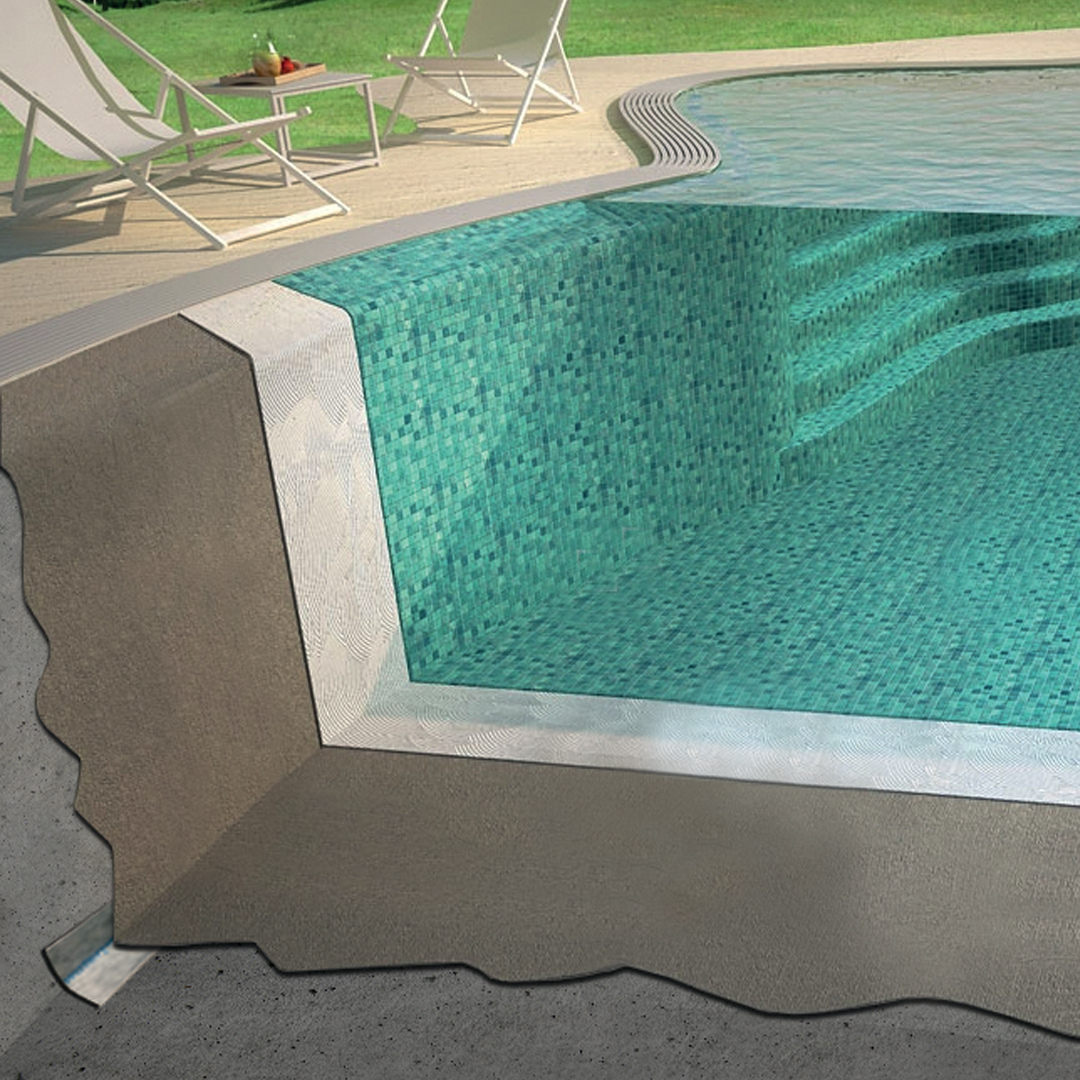

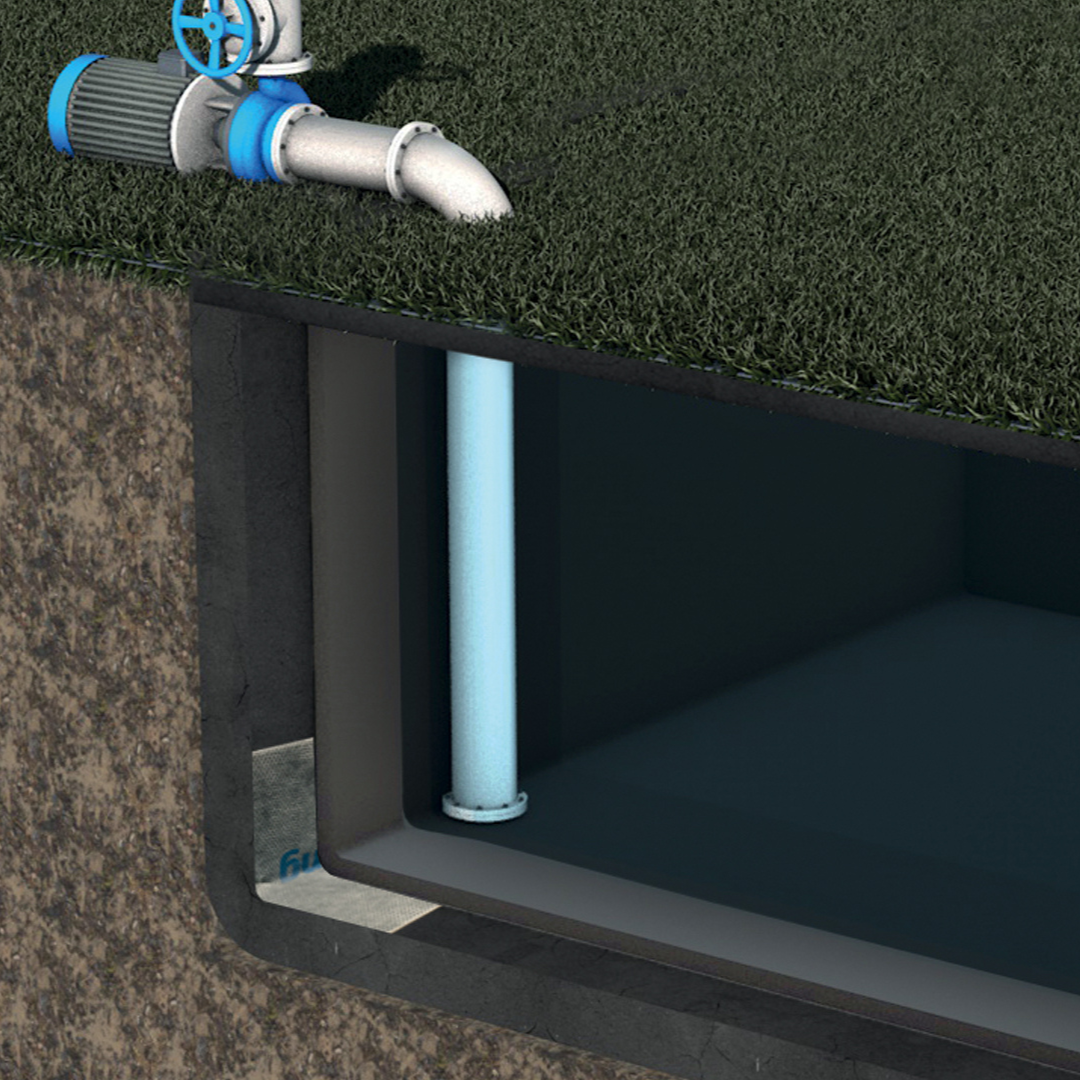

Our waterproofing systems are certified to EN 1504-2 Standards for the protection and repair of concrete structures, which is considered the gold standard in the building industry today. By protecting things such as swimming pools, tunnels, home foundations and more against water infiltration we enable a longer life for these systems which in turn reduces the frequency with which they need to be replaced with new concrete.

Our Hydro Monoelasto 100 waterproofing system for instance boasts impressive hydrophobic qualities while also being UV and chlorine resistant. This commendable result is achieved through a blend of hydraulic binders, graded aggregates and carefully chosen additives.

Our Licalastic 150 PU on the other hand offers outstanding elastomeric properties that make it the go-to liquid waterproofer for many in the construction industry. It too is EN 1504-2 certified and is at its best when employed in wet rooms, pool areas, saunas, outdoor kitchens and other, similar locations.

Our Licalastic Svart System is a 2-part liquid render system that is just as at home on indoor applications as it is in outdoor applications. Residential, commercial, great or small the Svart System displays admirable elastomeric properties and can be cold applied.

Restoring Balance to an Unbalanced System One Project at a Time

The global dependence on concrete is one of the great unspoken stories of our time. Where would we be without it? Hundreds of thousands of miles of roadway, airports, the world’s great bridges, skyscrapers, malls, stadiums, apartment blocks, safety barriers, light posts, swimming pools and countless other components of contemporary society are fashioned from concrete. Without it, our world would be a very different place.

But that is not enough reason to exempt the concrete industry from carbon accountability. Changes are urgently needed and products like Licata Waterproofing Systems are a step in the right direction helping to show the way for others.

If you are looking for a waterproofing system that will enable you to extend the useful life of your concrete structures while at the same time helping to reduce the impact concrete production has on the planet we are compelled to share, consider Licata’s selection of world-class EN 1504-2 certified waterproofing systems.