Advantages of Polymer Modification

Polymer-modified cement mortars offer significant advantages over traditional mortars. By incorporating polymers, these mortars exhibit enhanced adhesion, flexibility, and durability, making them ideal for various concrete repair applications. The improved bond strength ensures long-lasting repairs, even in challenging environments.

Additionally, the flexibility imparted by polymers allows the mortar to accommodate substrate movements without cracking. This characteristic is particularly beneficial in exterior applications where temperature fluctuations can cause expansion and contraction. Moreover, the enhanced durability extends the lifespan of repaired structures, reducing the need for frequent maintenance.

Applications of Polymer-Modified Mortars

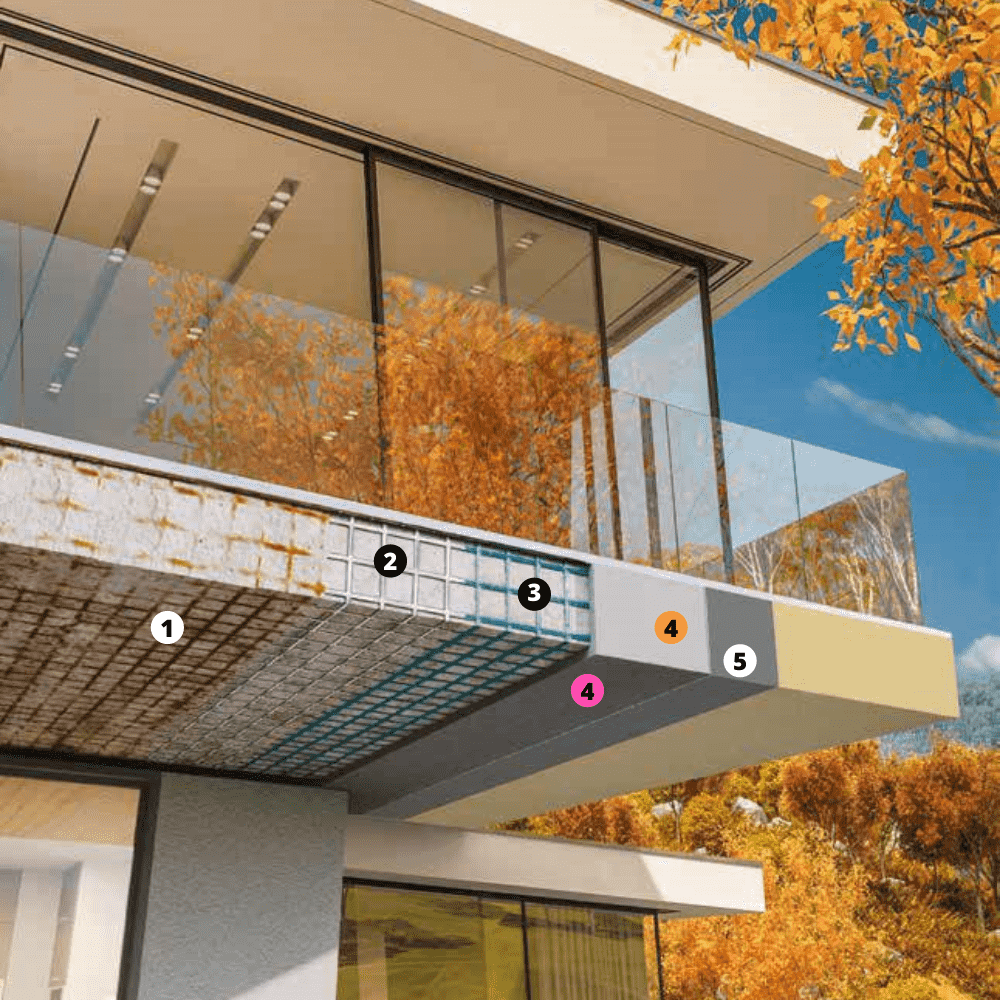

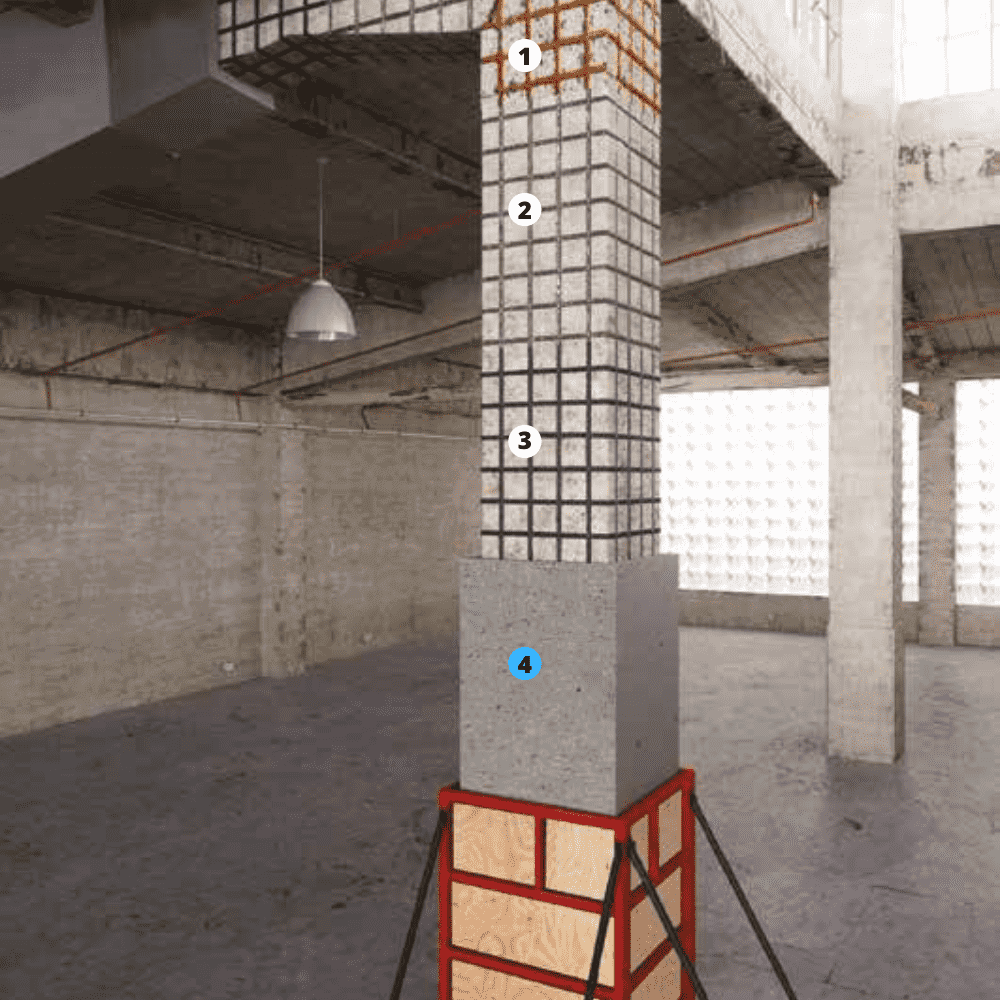

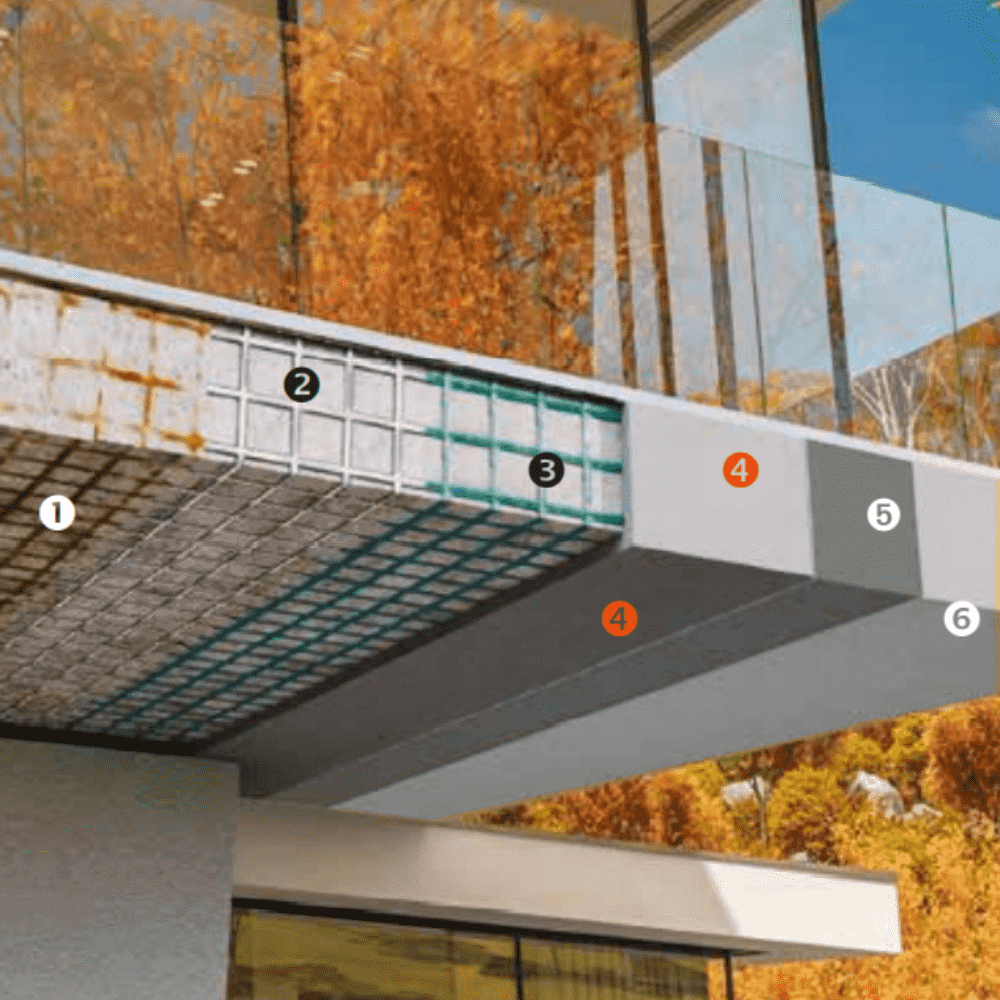

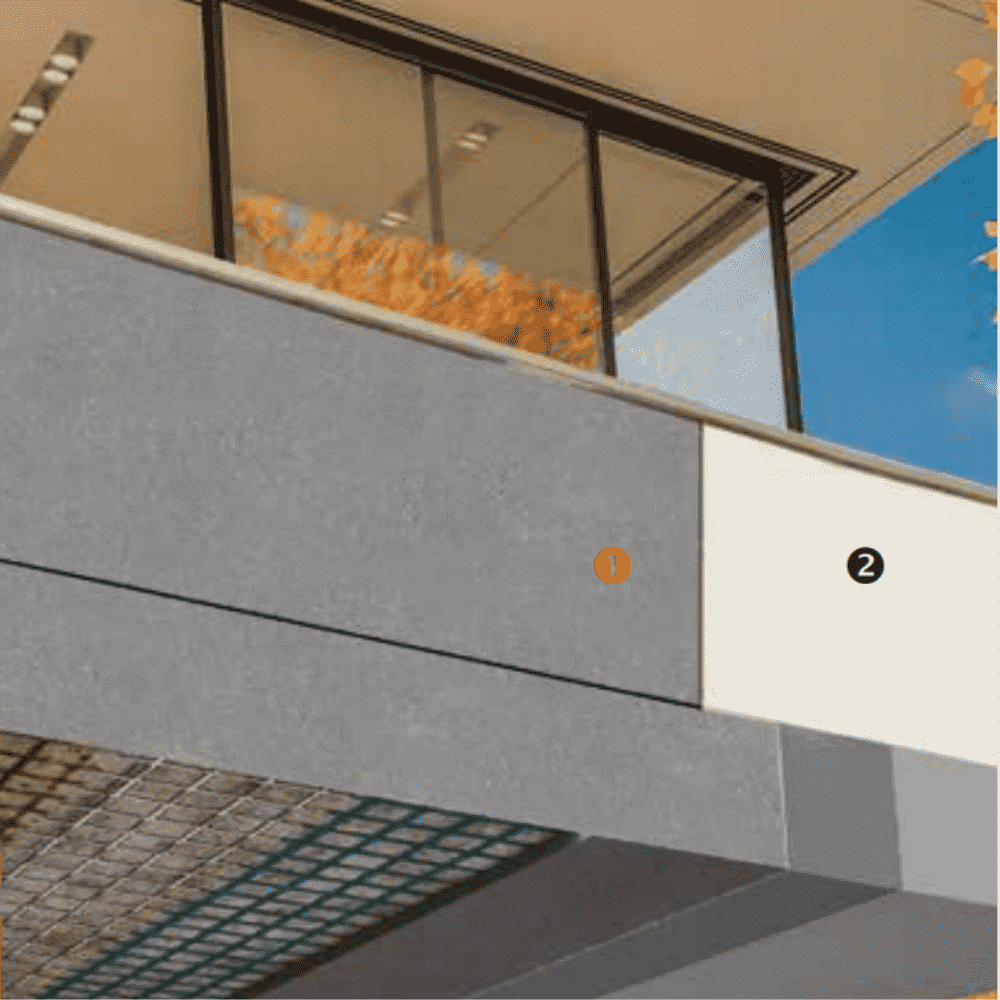

Polymer-modified mortars are versatile and suitable for both exterior and interior use. They are commonly employed in repairing damaged concrete surfaces, such as spalled areas, cracks, and voids. Their excellent adhesion to various substrates, including steel reinforcement, makes them ideal for structural repairs.

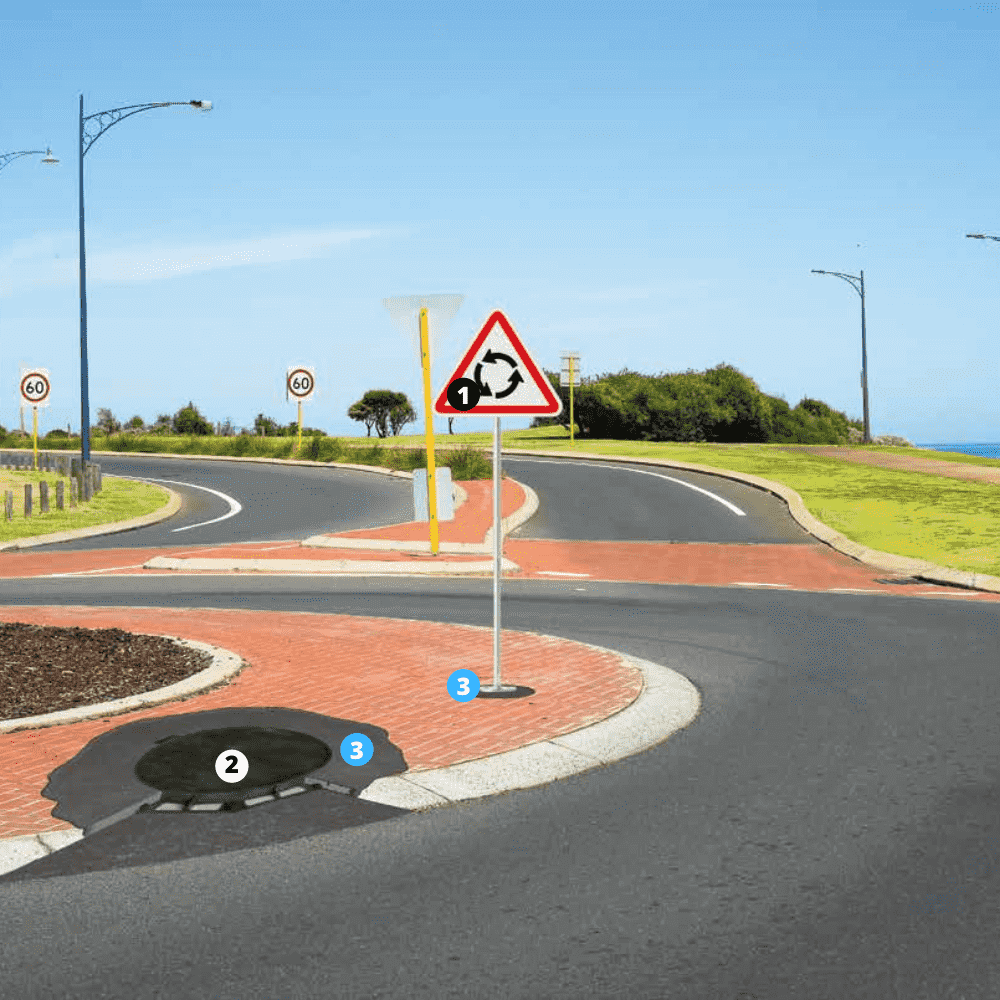

In addition to repairs, these mortars are used in waterproofing applications. For instance, Licata’s Hydro Monoelasto 100 is a single-component, polymer-modified cementitious waterproofing product designed to protect concrete structures from water ingress.

Comparison with Traditional Cement Mortars

Traditional Portland cement mortars, while effective in many scenarios, often lack the flexibility and adhesion required for durable repairs. In contrast, polymer-modified mortars provide superior bond strength and flexibility, ensuring that repairs can withstand structural movements and environmental stresses.

Moreover, the reduced permeability of polymer-modified mortars protects the underlying concrete from water penetration and carbonation, which can lead to deterioration over time. This makes them a more reliable choice for long-term durability in repair applications.

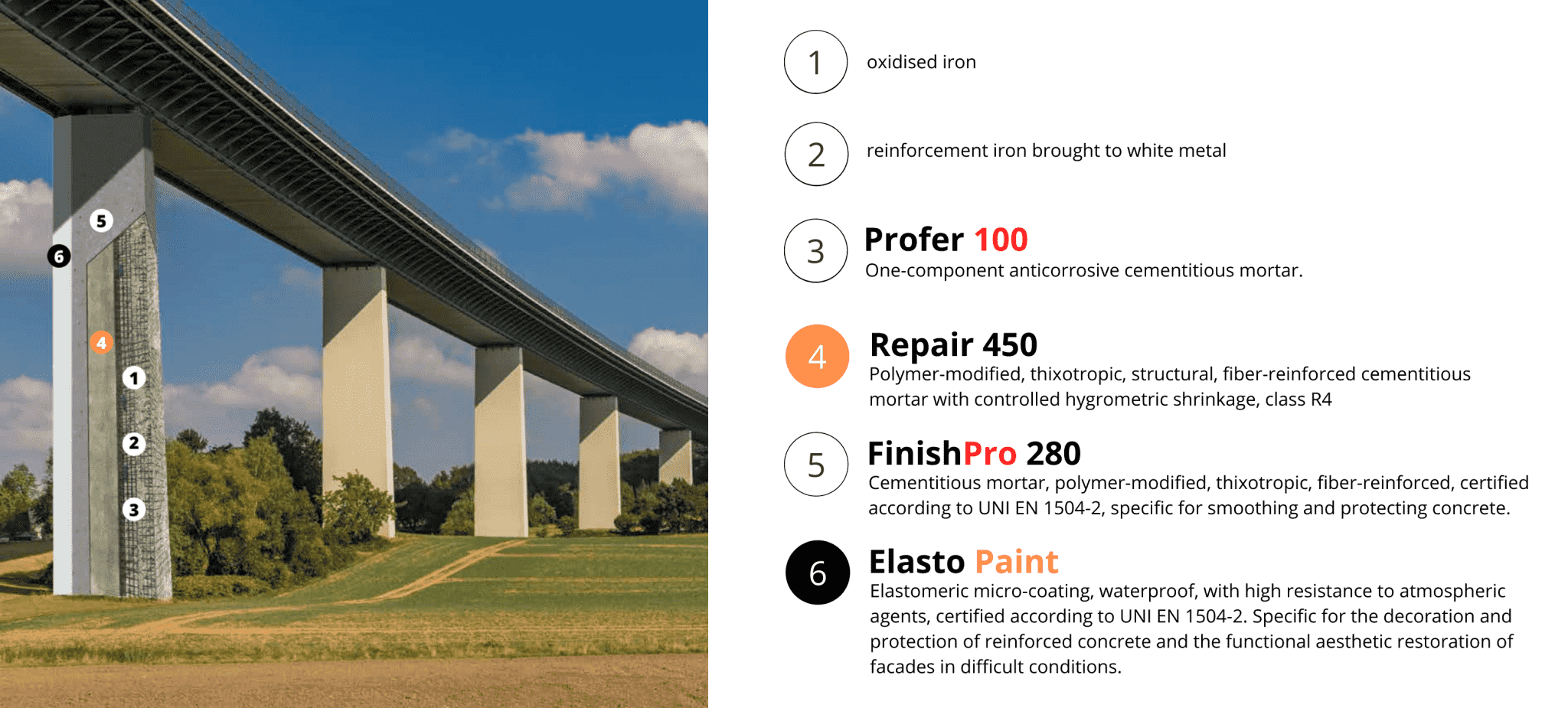

Licata’s Polymer-Modified Mortar Solutions

Licata offers a range of polymer-modified mortars adapted for various repair needs. The Repair 450 is a thixotropic, structural, fibre-reinforced mortar classified as R4 in accordance with UNI EN 1504-3, suitable for applications between 5 and 50 mm thickness.

Another notable product is the Repair 250 N, designed for restoration and protection of concrete structures. It offers high adhesion strength and mechanical performance, making it suitable for a wide range of repair applications.

Technical Specifications and Compliance

Licata’s polymer-modified mortars comply with European standards, ensuring quality and reliability. For example, the Repair 450 meets the requirements of UNI EN 1504-3 for structural repair mortars, classified as R4, indicating high performance in terms of compressive strength and adhesion.

Similarly, the Hydro Monoelasto 100 is certified in accordance with UNI EN 14891 as a waterproof cement mortar, resistant to chlorine and with crack-bridging ability at low temperatures, making it suitable for waterproofing applications.

Incorporating these polymer-modified mortars into your repair projects ensures adherence to industry standards and enhances the longevity and durability of the repaired structures.