I’m Here To Assist You

Licata Building System needs your contact information to contact you about our products and services. Our specification manager will contact you shortly in regard to your enquiry.

Our concrete skimming mortars are ideal for both internal and external surfaces, providing a flawless finish for uneven or damaged areas. Whether you’re working on repairing concrete structures or preparing a surface for coatings, our mortars ensure dependable performance and long-lasting results.

Designed to meet the demands of modern construction, our skimming mortars can be applied to lime mortar renders, concrete surfaces, and even partially covered areas. They offer exceptional flexibility, making them suitable for a wide range of internal or external applications.

We prioritise quality in our skimming mortars, which offer high bonding strength to ensure durability and stability. This makes them perfect for concrete repair projects where adhesion and structural integrity are crucial.

Our water-repellent formula helps protect surfaces from moisture, preserving the life of external concrete structures. Additionally, fibre-reinforced options provide extra durability, even under direct exposure to changing weather conditions.

Selecting the right mortar for your project is key to achieving the best results. Our team can help you choose the ideal solution, whether you need a repair mortar for damaged concrete or a product to meet specific compressive strength requirements.

For projects requiring a smooth, natural finish, our skimming mortars are compatible with decorative options like quartz paint or scratch effect plastic coatings. With their special composition, they meet the minimum requirements for long-term reliability.

Applying our mortars in two coats ensures a uniform finish and enhances durability. Using a sponge float during the final stage can help create a seamless surface, perfect for both practical use and aesthetic appeal.

Ensure application in good weather conditions for optimal results. Always adhere to our guidelines for maximum thickness per coat and proper mixing techniques to achieve the best finish.

At Licata, quality control is at the heart of everything we do. Our concrete surface protection systems are rigorously tested to meet conformity assessment standards and deliver consistent performance.

We’re dedicated to supporting your construction and renovation needs, from concrete repair to creating strong, beautiful finishes. Trust our expertise and product range to achieve outstanding results on every project.

At Licata, we recommend allowing newly poured concrete to cure properly before applying any concrete skimming mortar. Once the surface is firm, dry and prepared, our systems ensure strong adhesion and reliable results across both internal and external concrete applications.

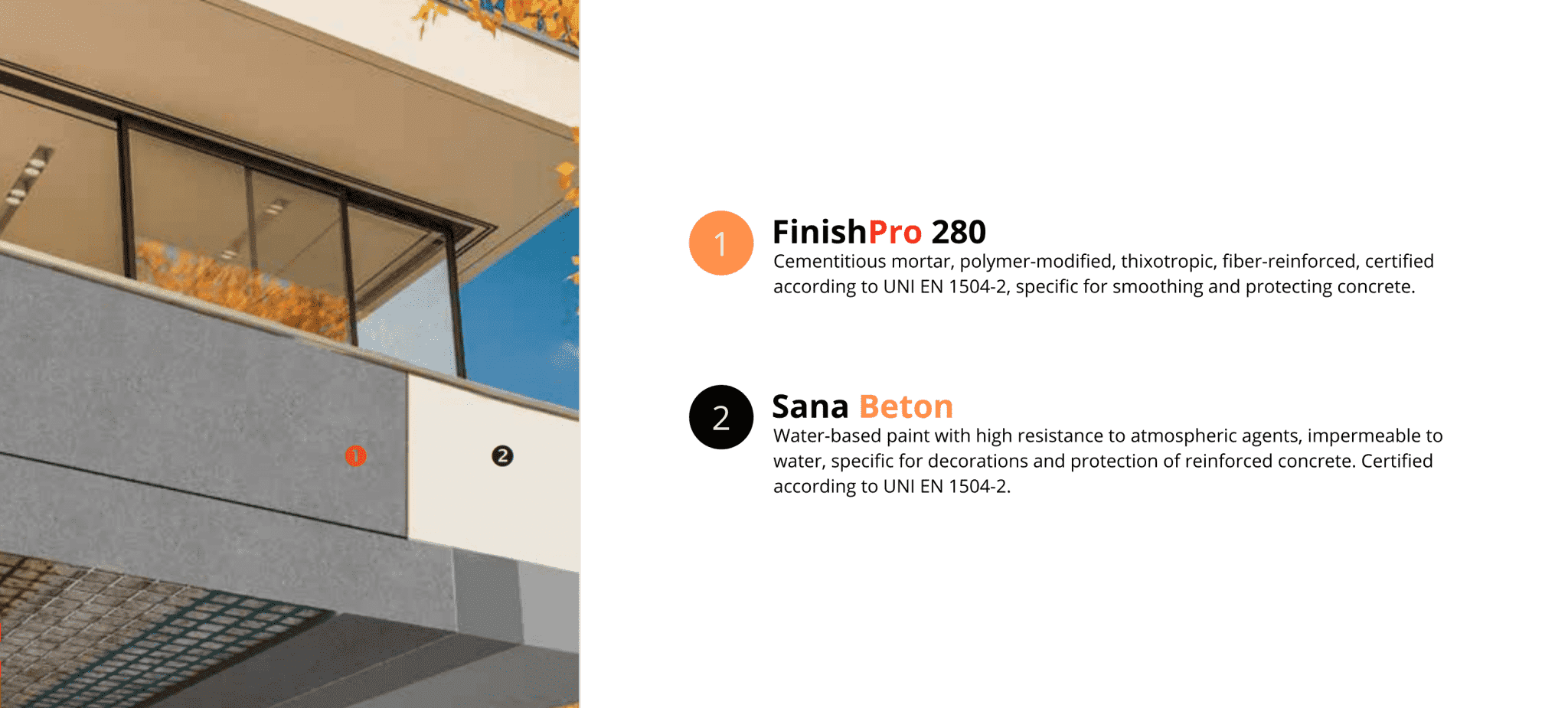

FinishPro 280 is specially developed for repairing concrete structures and achieving a smooth, natural finish. The product’s high bonding strength and fibre-reinforced formulation make it a dependable choice when working on partially covered or exposed concrete surfaces.

Our skimming mortar is designed for flexibility, but we advise keeping the coat within the recommended maximum thickness of around 3 to 5 mm per layer. Applying in two coats helps maintain a uniform finish while strengthening overall durability and surface protection.

Whether you’re repairing concrete or finishing lime mortar render, following the proper thickness guidelines ensures your concrete surface protection systems meet long-term expectations. Always apply with a flat metal trowel and finish with a sponge float for best results.

For most concrete repair projects using Licata’s cementitious skimming mortar, mechanical preparation of the base is often enough. But where the concrete is dusty or highly absorbent, a suitable primer can improve bonding performance and reduce surface absorption.

Our skimming systems are tested through strict quality control and conformity assessment processes. When repairing concrete or working on lime mortar surfaces, proper surface prep is just as important as choosing the right mortar for the job.

Licata’s skimming mortar provides an excellent aesthetic finish but isn’t made to withstand heavy wear on its own. To protect external surfaces or high-traffic areas, you can top with decorative coatings like quartz paint or scratch effect plastic coatings.

If you’re decorating internal concrete or repairing external concrete walls, pairing our special composition mortar with a protective coating extends the life of your concrete structures. This combination ensures the surface meets the minimum requirements for durability and water resistance.

Our skimming mortar systems are formulated with selected aggregates and special admixtures to ensure reliable working time. Under good weather conditions, you’ll typically have 30 to 40 minutes to apply and shape each coat before it starts to set.

This window allows enough time to work with a flat metal trowel and finish off with a sponge float. Whether you’re working on internal or external surfaces, always mix and apply within the time recommended in the technical sheet for that product.

Licata’s FinishPro 280 concrete skimming mortar is ideal for a wide range of surfaces including lime mortar, concrete, brickwork and even insulating panels. It’s especially effective when repairing concrete or straightening surfaces for decorative finishing.

You can use it for both internal and external concrete works, and it’s compatible with decorative finishes such as quartz paint, coloured finishing products or scratch effect plastic coatings. The mortar’s water repellent properties and fibre reinforcement make it suitable even under direct exposure.