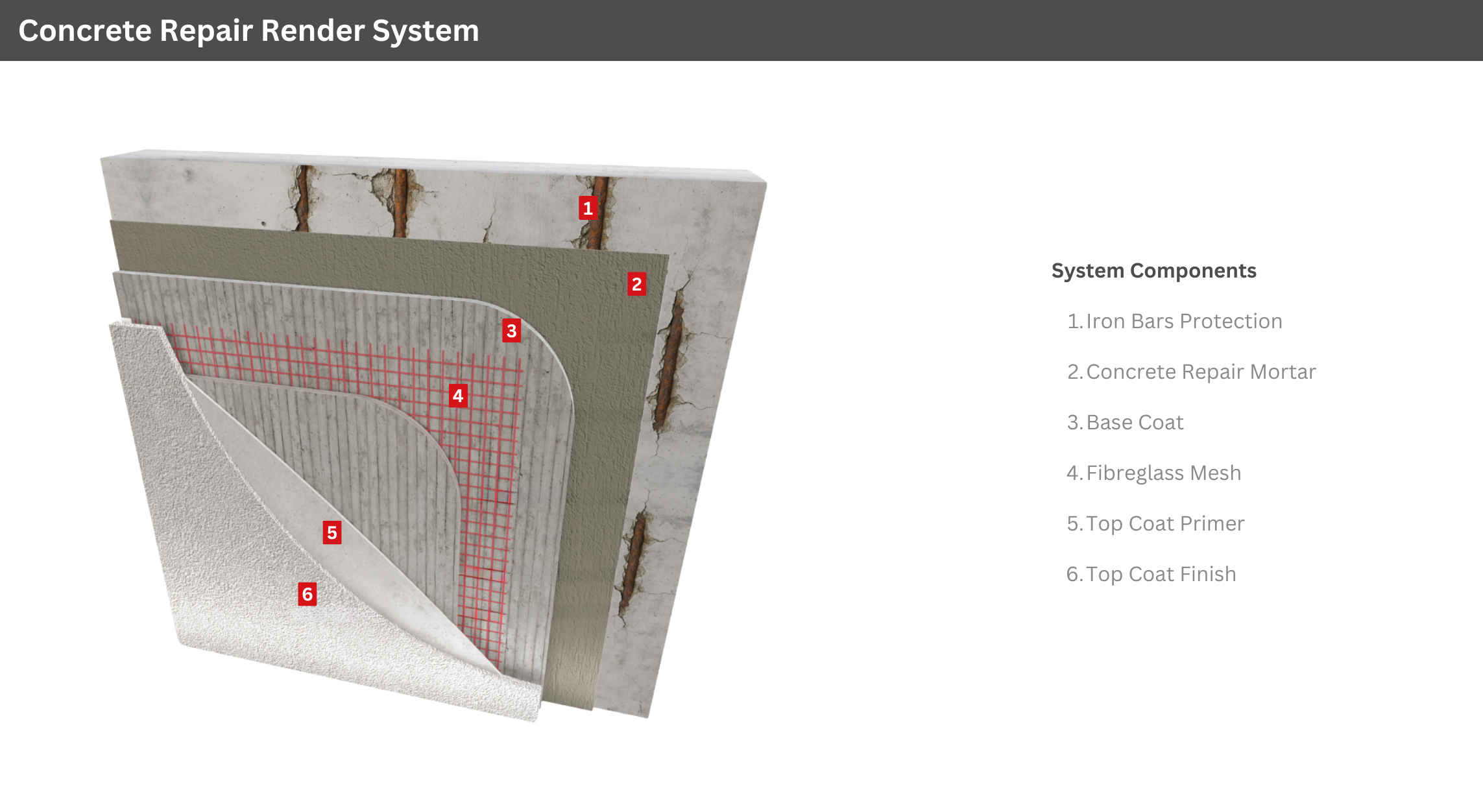

Licata’s Concrete Repair Render System is engineered for the restoration and protection of damaged or deteriorating concrete surfaces. This system provides excellent adhesion, flexibility, and compressive strength, making it ideal for repairing cracks, spalled areas, and surface defects without full structural replacement. Designed to withstand harsh weather conditions, it offers high breathability, water resistance, and protection against carbonation and chloride penetration. Suitable for vertical and overhead applications, it can be applied by hand or machine and finished with a compatible decorative coating. Perfect for refurbishing concrete façades, soffits, and structural elements in both residential and commercial settings.

I’m Here To Assist You

Licata Building System needs your contact information to contact you about our products and services. Our specification manager will contact you shortly in regard to your enquiry.