I’m Here To Assist You

Licata Building System needs your contact information to contact you about our products and services. Our specification manager will contact you shortly in regard to your enquiry.

Authentic brick finishes. Lightweight, durable, and ideal for modern construction.

The Authentic Brick Look - Without the Weight

Achieve traditional brickwork aesthetics with the flexibility and performance of a modern façade solution. Licata’s real clay brick slips are lightweight, durable, and compatible with a wide range of substrates — from insulation boards to render carrier boards and solid masonry.

Licata Clay Brick Slips combine genuine kiln-fired clay with cutting-edge façade systems to deliver the timeless beauty of brick without the bulk and limitations of traditional masonry. Ideal for both new build and retrofit projects, our brick slips are available in over 30 colours and finishes, offering unmatched design flexibility for architects and specifiers.

Whether you're working on a timber frame, modular build, high-rise EWI system, or solid wall renovation, Licata’s complete brick slip systems provide the aesthetic finish of real brick with streamlined installation and certified performance.

Licata clay slips are a versatile thin brick cladding that simulates the look of traditional clay brickwork whilst providing greater insulation and more flexibility of style and application. Our clay slips come in a range of sizes, colours and textures, and are suitable for both internal and external use. Providing modern insulation and greater adaptability whilst giving you that traditional brickwork look that is so popular in the UK. Suitable for both low and high rise buildings, this is an A2 fire classification brick slip system in accordance with BS EN 13501-1 : 2007.

Whether you're working on a timber frame, modular build, high-rise EWI system, or solid wall renovation, Licata’s complete brick slip systems provide the aesthetic finish of real brick with streamlined installation and certified performance.

Features

- Fully accredited to the A2-s1, d0 fire safety standard.

- Three manufacturing processes to expand the choice of texture, colour and finish.

- Suitable for new and existing buildings, including high-rise.

- Freedom in pattern design.

- Standard formats and corner solutions are available.

Clay Brick Slips Colour Range

Our clay brick slips are available in a wide variety of colours and finishes to suit both traditional and contemporary designs. To see the complete selection and find the perfect match for your project, browse our full Clay Brick Slips Brochure.

Leading Italian

Manufacturer

BBA Certified

Insulated Systems

Licata 10 Years

Product Warranty

National

Insulation

Association

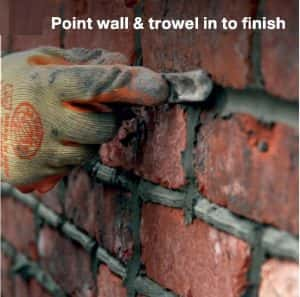

Please check the brick slips before installing. The substrate should be clean, dust free, workable, solid and even. Any wallpaper or other residues should be removed before installing the brick slips. We recommend priming the substrate. Spread a suitable flexible adhesive with a toothed spreader by “buttering” both on the back of the slip and on the wall (“buttering-floating”). A string line will be helpful.